There are many reasons why you are in good hands with us, for example:

- Cutting machines and grinding machines are our absolute main products - and therefore enjoy the highest priority in all our activities

- Experience since 1965

- We do the complete engineering (mechanical, electrical, software) ourselves, with highly qualified, motivated personnel and state-of-the-art planning software

- We manufacture the core components of our machines ourselves

- Pre-commissioning of the assembled machines in our factories before delivery

- Installation guidance and commissioning at your facility, performed by highly compentent people

- Continuous and targeted research and development (in-house technical center with test and demonstration machines)

- Strategic cooperation with the leading manufacturers of cutting and grinding wheels and saw blades

- Comprehensive know-how for cutting systems and grinding systems

- Intensive cooperation with other leading technology suppliers (e.g., for testing and analysis systems).

- Broad technological knowledge and process know-how

- We deliver the highest quality. We are ISO 9001: 2015 certified

In-house Test and Development Machines

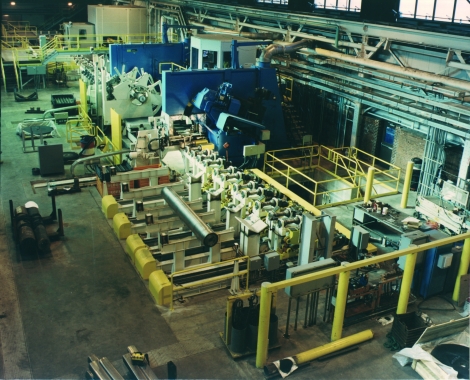

Since establishing our steel cutting and grinding machines division more than 50 years ago, BRAUN has developed into a global technology leader in this field. Significant milestones (see below) illustrate this development. Targeted research and development, our own engineering capacities for all areas, in-house manufacturing capabilities, a team of well-trained and motivated professionals and strategic cooperation with various technology partners form the basis for our comprehensive expertise in cutting and grinding - all to the benefit of our customers.

1965

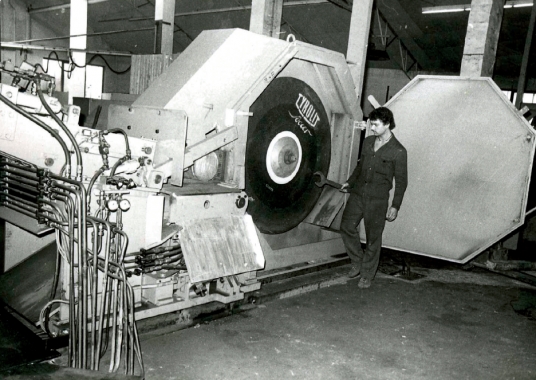

Construction of the first cutting machine (dry cutting - a new innovative technology)

1969

Development of the first large-scale abrasive cut-off machine with a 1250 mm (49") blade diameter

1990

First cut-to-length abrasive cut-off machine for layer cutting steel bars at the cooling bed exit

1997

First integrated abrasive cut-off machine for index cutting of large cross-section billets, ingots and electrodes.

1999

First multi-functional HP (high-pressure / high-performance) grinding machine for billets

2005

First longitudinal grinding machine for large seamless tubes.

2007

First HP Grinder for helical grinding of round stainless steel bars, billets and ingots.

2009

First high-performance abrasive cut-off machines with a 2,000 mm (79") diameter cutting wheel (for 3 different applications: at the radial forging machine exit, at the forging press exit, and for billet sizing).

2012

First HP grinding machine for titanium billets and slabs

2015

First convertible abrasive cut-off machine / hot friction saw for cutting special quality round bars as well as merchant quality structural steel profiles in layers. New product line BRAUN-SILVERCUT with small ( 800 mm / 32" cutting wheel) wet and dry cutting machines for production and metallographic applications. First grinding machine for deburring steel slabs.

2016

First HP grinding machine with automated systems for product recognition and crack detection for automatic grinding of local surface defects. First convertible abrasive cut-off grinding machine / cold circular saw (factory test and demonstration machine in the BRAUN technical center).

Today

BRAUN is a technology leader for cutting and grinding with a global presence - with 3 locations (Austria, USA, China) and 26 sales and service partners for 45 countries on all 5 continents.

Contact

Contact